1996 Evinrude 70 hp: Alarm Horn

-

thediscusthrower

- Posts: 55

- Joined: Tue May 16, 2017 1:05 pm

- Location: Southern NJ

1996 Evinrude 70 hp: Alarm Horn

I've got another hurdle to jump over as of yesterday. I have a 1996 Evinrude 70hp that works off an audible alarm system (not the gauge) and when I went to start it, the "horn" [as it's called] blared continuously, even though nothing was going on. Is this something I can reset by removing power from the battery terminal? What else could be causing this?

Please help. Bob

Please help. Bob

Last edited by thediscusthrower on Fri Oct 20, 2017 2:43 pm, edited 1 time in total.

Re: 1996 Evinrude 70 hp: Alarm Horn

If you just turn on the key and not start engine does the alarm sound?

IMHO I would check the oil sensor and the engine temp sensor.

M

IMHO I would check the oil sensor and the engine temp sensor.

M

-

thediscusthrower

- Posts: 55

- Joined: Tue May 16, 2017 1:05 pm

- Location: Southern NJ

Re: 1996 Evinrude 70 hp: Alarm Horn

Yes.InVision wrote:If you just turn on the key and not start engine does the alarm sound?

-

thediscusthrower

- Posts: 55

- Joined: Tue May 16, 2017 1:05 pm

- Location: Southern NJ

Re: 1996 Evinrude 70 hp: Alarm Horn

jimh wrote:Compare with normal operation as described at

http://continuouswave.com/whaler/refere ... gnals.html

Boat is on the trailer and the engine is cold as well as running at idle after initial start-up. Exhaust smoke is blue, indicating oil is being burned with the gas.

Of course, it's a process of elimination regarding a continuous "horn":

1) Engine is not overheating because it's at cold start on the muffs and running at idle

2) Not sure about a fuel restriction because it starts up fine and idles fine

Last edited by thediscusthrower on Thu Oct 19, 2017 9:24 pm, edited 1 time in total.

Re: 1996 Evinrude 70 hp: Alarm Horn

Your problem is actually pretty common. Under the cowl there is a big red plug and it's common for corrosion to start on the pins causing intermittent contact and sound the warning horn. I would start there and unplug and clean the contacts and plug back together. Also make sure you use the bent stainless wire that keeps the two halves together. That is the free and simple place I'd start. If that does not work, then I'd start looking at sensors and harnesses, but that is more involved.

I just had this happen on a 1995 Evinrude 60hp which is the same motor and done this fix on numerous Johnson/Evinrudes over the years.

D-

I just had this happen on a 1995 Evinrude 60hp which is the same motor and done this fix on numerous Johnson/Evinrudes over the years.

D-

Re: 1996 Evinrude 70 hp: Alarm Horn

I would bypass the oil and temp sensors and see if alarm goes away after you clean the "Red Plug".

Downloading a service manual with flow charts on troubleshooting would also help. I found a bad sensor in oil tank on our Mercury OPTI 150 by purchasing a service manual off of eBay.

Good Luck !!

M

Downloading a service manual with flow charts on troubleshooting would also help. I found a bad sensor in oil tank on our Mercury OPTI 150 by purchasing a service manual off of eBay.

Good Luck !!

M

-

thediscusthrower

- Posts: 55

- Joined: Tue May 16, 2017 1:05 pm

- Location: Southern NJ

Re: 1996 Evinrude 70 hp: Alarm Horn

dtmackey wrote:Your problem is actually pretty common. Under the cowl there is a big red plug and it's common for corrosion to start on the pins causing intermittent contact and sound the warning horn. I would start there and unplug and clean the contacts and plug back together. Also make sure you use the bent stainless wire that keeps the two halves together. That is the free and simple place I'd start. If that does not work, then I'd start looking at sensors and harnesses, but that is more involved.

I just had this happen on a 1995 Evinrude 60hp which is the same motor and done this fix on numerous Johnson/Evinrudes over the years.

D-

This is another area where I have not touched since restoration work back in 2005. I know the connector and will take a look-see in the morning. Like my Dad always said "look for something simple first before you start pulling stuff apart." Dad was always right. I'll let you know how I make out.

Bob

Last edited by thediscusthrower on Thu Oct 19, 2017 9:11 pm, edited 1 time in total.

-

thediscusthrower

- Posts: 55

- Joined: Tue May 16, 2017 1:05 pm

- Location: Southern NJ

Re: 1996 Evinrude 70 hp: Alarm Horn

InVision wrote:I would bypass the oil and temp sensors and see if alarm goes away after you clean the "Red Plug".

Downloading a service manual with flow charts on troubleshooting would also help. I found a bad sensor in oil tank on our Mercury OPTI 150 by purchasing a service manual off of eBay.

Good Luck !!

M

I was going through the service manual earlier and it's pretty much the same as the link Jim provided. The problem is that the symptom(s) don't match anything listed in the troubleshooting tables.

Re: 1996 Evinrude 70 hp: Alarm Horn

The circuit that causes the alarm to sound is really quite simple. There is a 12-Volt feed to the alert sounder. The alert sounder operates when the other side of the circuit goes to ground. There are several sensors that are wired to the alarm. The sensors are essentially switches, and they operate when some aspect of the engine which they are designed to monitor reaches a temperature or pressure or voltage or some other parameter that exceeds the design limit.

This arrangement of several switches in common with one circuit is called a WIRED-OR. It means that ANY one of the switches can close and cause the alarm to sound.

Your situation is that part of the system is causing the alarm to sound continuously. There is a general aspect of ALL alarm system when there is an alarm condition. There are three general possibilities:

--the entire system is working normally, there is some parameter of the engine that is out of tolerance, a sensor has detected it, and the alarm is sounding; or,

--there is a defect in the alarm system, one of the sensors is malfunctioning, and it is signalling a false alarm; or,

--there is a defect in the alarm system in the alert sounder itself; the alert sounder is just sounding all by itself, without any sensor causing it.

If you apply these three possibilities to your engine, you can diagnose the problem fairly easily. Use this procedure:

--located all the sensors involved in the alarm system; disconnect them all;

--if the cause was a bad sensor, the aural alert should silence now;

--if the aural alert continues to sound, the aural alert is probably defective;

--if the aural alert is silent, then reconnect the sensor leads, one by one; the sensor that causes the aural alert to begin sounding is probably defective.

This arrangement of several switches in common with one circuit is called a WIRED-OR. It means that ANY one of the switches can close and cause the alarm to sound.

Your situation is that part of the system is causing the alarm to sound continuously. There is a general aspect of ALL alarm system when there is an alarm condition. There are three general possibilities:

--the entire system is working normally, there is some parameter of the engine that is out of tolerance, a sensor has detected it, and the alarm is sounding; or,

--there is a defect in the alarm system, one of the sensors is malfunctioning, and it is signalling a false alarm; or,

--there is a defect in the alarm system in the alert sounder itself; the alert sounder is just sounding all by itself, without any sensor causing it.

If you apply these three possibilities to your engine, you can diagnose the problem fairly easily. Use this procedure:

--located all the sensors involved in the alarm system; disconnect them all;

--if the cause was a bad sensor, the aural alert should silence now;

--if the aural alert continues to sound, the aural alert is probably defective;

--if the aural alert is silent, then reconnect the sensor leads, one by one; the sensor that causes the aural alert to begin sounding is probably defective.

-

thediscusthrower

- Posts: 55

- Joined: Tue May 16, 2017 1:05 pm

- Location: Southern NJ

Re: 1996 Evinrude 70 hp: Alarm Horn

Pictures of that red connector at the back of the powerhead indicate an open circuit due to excessive corrosion.

https://scontent-iad3-1.xx.fbcdn.net/v/ ... e=5A6A281D

https://scontent-iad3-1.xx.fbcdn.net/v/ ... e=5A7A1D42

Can these connections be "pushed out," cleaned and/or replaced individually or do I have to replace the entire thing?

What are these type of male connectors called?

Not so proficient in electrical stuff even though I took (2) semester of physics in college.

P.S. I think it's time for a complete look at all the similar "connections" in the engine loom so I can be confident that I don't have to turn into a "mechanic on the water." I don't understand why these connectors are not protected by dielectric grease?

Bob

https://scontent-iad3-1.xx.fbcdn.net/v/ ... e=5A6A281D

https://scontent-iad3-1.xx.fbcdn.net/v/ ... e=5A7A1D42

Can these connections be "pushed out," cleaned and/or replaced individually or do I have to replace the entire thing?

What are these type of male connectors called?

Not so proficient in electrical stuff even though I took (2) semester of physics in college.

P.S. I think it's time for a complete look at all the similar "connections" in the engine loom so I can be confident that I don't have to turn into a "mechanic on the water." I don't understand why these connectors are not protected by dielectric grease?

Bob

Re: 1996 Evinrude 70 hp: Alarm Horn

IMHO I would replace the connector. Then I would apply corrosion-X to both sides before connecting.

M

M

Re: 1996 Evinrude 70 hp: Alarm Horn

Red plug culprit. This should be an annual maint item to disconnect, inspect and put corrosion block on the pins.

That plug is part of the harness and if it were my motor, I would clean up what is left and continue using that plug. I would also tap into the missing pin where the wires go into the plug and install a male/female jumper around it (simply bypass for that circuit). That's the simplest repair short of replacement.

Or buy a used one. https://www.ebay.com/itm/1992-1996-Johnson-Evinrude-Motor-Cable-Wiring-Harness-584401-50-60-65-70-HP-/362050194268?epid=1022082438&hash=item544bdf8b5c:g:NJQAAOSwiX5Zd6Y5&vxp=mtr

You can clean the plug with CocaCola (it contains phosphoric acid) and a toothbrush.

D-

That plug is part of the harness and if it were my motor, I would clean up what is left and continue using that plug. I would also tap into the missing pin where the wires go into the plug and install a male/female jumper around it (simply bypass for that circuit). That's the simplest repair short of replacement.

Or buy a used one. https://www.ebay.com/itm/1992-1996-Johnson-Evinrude-Motor-Cable-Wiring-Harness-584401-50-60-65-70-HP-/362050194268?epid=1022082438&hash=item544bdf8b5c:g:NJQAAOSwiX5Zd6Y5&vxp=mtr

You can clean the plug with CocaCola (it contains phosphoric acid) and a toothbrush.

D-

Re: 1996 Evinrude 70 hp: Alarm Horn

I do not have one of these motors so I may ask a stupid question...

Curious about the plug in general. Could you not put solder connectors on each of the wires and heat shrink them. What does the plug buy you besides misery?

M

Curious about the plug in general. Could you not put solder connectors on each of the wires and heat shrink them. What does the plug buy you besides misery?

M

Re: 1996 Evinrude 70 hp: Alarm Horn

InVision wrote:I do not have one of these motors so I may ask a stupid question...

Curious about the plug in general. Could you not put solder connectors on each of the wires and heat shrink them. What does the plug buy you besides misery?

M

The plug is a means of connecting the main wiring harness from the control box and ignition to the motor and plugs are widely used by nearly all the outboards made to speed rigging time and allow for disconnecting for troubleshooting. Yes, one could simply remove the plug and use mechanical crimps or solder, but soldering wire is frowned up in marine setting, especially where vibration is present.

The Evinrude plug is reliable, just needs to be cleaned and maintained, which is tends to become an overlooked item. The worst design was by Merc on the 70 - 80 inline 4 and 6 cylinder motors where a similar type plug was used and it connected at he lower cowling of the motor and was constantly getting water spray. Those had lots of problems.

D-

-

thediscusthrower

- Posts: 55

- Joined: Tue May 16, 2017 1:05 pm

- Location: Southern NJ

Re: 1996 Evinrude 70 hp: Alarm Horn

I cleaned-up the connector plug, installed a NEW male connector and cleaned-up the existing female. Still sounding alarm/horn continuously. WTF?!!!

-

thediscusthrower

- Posts: 55

- Joined: Tue May 16, 2017 1:05 pm

- Location: Southern NJ

Re: 1996 Evinrude 70 hp: Alarm Horn

InVision wrote:I do not have one of these motors so I may ask a stupid question...

Curious about the plug in general. Could you not put solder connectors on each of the wires and heat shrink them. What does the plug buy you besides misery?

M

I went over to my local boat yard and the price of the wiring harness was close to $300. I can't afford that because I'm out of work and barely getting by. I asked if I could cut the entire "plug" out and just butt connect the wiring together. Answer was yes but not sure I need or what to do that at the moment.

Last edited by thediscusthrower on Fri Oct 20, 2017 3:39 pm, edited 2 times in total.

-

thediscusthrower

- Posts: 55

- Joined: Tue May 16, 2017 1:05 pm

- Location: Southern NJ

Re: 1996 Evinrude 70 hp: Alarm Horn

thediscusthrower wrote:InVision wrote:I do not have one of these motors so I may ask a stupid question...

Curious about the plug in general. Could you not put solder connectors on each of the wires and heat shrink them. What does the plug buy you besides misery?

M

I went over to my local boat yard and the price of the wiring harness was close to $300. I can't afford that because I'm out of work and barely getting by. I asked if I could cut the entire "plug" out and just butt connect (with shrink wrap ends) the wiring together. Answer was yes but not sure I need or what to do that at the moment.

Last edited by thediscusthrower on Fri Oct 20, 2017 3:38 pm, edited 1 time in total.

-

thediscusthrower

- Posts: 55

- Joined: Tue May 16, 2017 1:05 pm

- Location: Southern NJ

Re: 1996 Evinrude 70 hp: Alarm Horn

dtmackey wrote:Red plug culprit. I would also tap into the missing pin where the wires go into the plug and install a male/female jumper around it (simply bypass for that circuit). That's the simplest repair short of replacement.

I removed/pushed-out the individual wire from the male-side of the plug, as all the wires are in plain view. However, the female part is configured like a regular "house" wire; no wires showing but just a black sheath. I would have to slice that with a razor knife in order to get the other wire out. Is that what should do? Rig the workaround wire, tape the rest up and leave it alone before reconnecting everything to test the horn problem?

Bob

Re: 1996 Evinrude 70 hp: Alarm Horn

I would hardwire that circuit around the plug.

Once you start hacking the red plug with a razor blade you might as well abandon the whole plug.

D-

Once you start hacking the red plug with a razor blade you might as well abandon the whole plug.

D-

-

thediscusthrower

- Posts: 55

- Joined: Tue May 16, 2017 1:05 pm

- Location: Southern NJ

Re: 1996 Evinrude 70 hp: Alarm Horn

dtmackey wrote:I would hardwire that circuit around the plug.

Once you start hacking the red plug with a razor blade you might as well abandon the whole plug.

D-

I know but I have to cut the one side in order to see where the female wire end is. There's no other option in order to get the wire out.

https://scontent-iad3-1.xx.fbcdn.net/v/ ... e=5A7DD106

Re: 1996 Evinrude 70 hp: Alarm Horn

OK, you didn't cut the connector like I was thinking and it's still good. You could also do the same to the other side and then take an ohm meter and testing each leg of the connector.

D-

D-

-

thediscusthrower

- Posts: 55

- Joined: Tue May 16, 2017 1:05 pm

- Location: Southern NJ

Re: 1996 Evinrude 70 hp: Alarm Horn

dtmackey wrote:OK, you didn't cut the connector like I was thinking and it's still good. You could also do the same to the other side and then take an ohm meter and testing each leg of the connector.

D-

How do I do that? I have a multi-meter but not a lot of experience on how to use it. I was also considering Jim's suggestions of unhooking the individual sensors and then reconnecting one at a time. Who knows, the actual horn may be the culprit but I don't have a spare to check its function, as suggested in the factory manual.

What to do first?

Bob

-

thediscusthrower

- Posts: 55

- Joined: Tue May 16, 2017 1:05 pm

- Location: Southern NJ

Re: 1996 Evinrude 70 hp: Alarm Horn

jimh wrote:If you apply these three possibilities to your engine, you can diagnose the problem fairly easily. Use this procedure:

--located all the sensors involved in the alarm system; disconnect them all;

--if the cause was a bad sensor, the aural alert should silence now;

--if the aural alert continues to sound, the aural alert is probably defective;

--if the aural alert is silent, then reconnect the sensor leads, one by one; the sensor that causes the aural alert to begin sounding is probably defective.

Jim,

What do these "sensors" look like? Do you have any reference pics?

Bob

Re: 1996 Evinrude 70 hp: Alarm Horn

Sensors use brown or black wires. Here is what the temp sensor looks like on another Evinrude, but they are all similar.

All sensor wires under the cowl are brown. Here's the temp sensor

https://i.ytimg.com/vi/M_bITnAPp8Y/maxresdefault.jpg

Here's the VRO tank sensor that connects to a black wire that then exists the motor and goes to the VRO tank.

http://i28.tinypic.com/2nq7dhl.jpg

Should be another brown wire that goes to the VRO though another connector if my memory serves be correct.

A schematic would serve you well. This is from an 84 motor, but the VRO circuit should be the same or similar.

http://maxrules.com/graphics/omc/wiring/78-84_3-CYL_EL.jpg

D-

All sensor wires under the cowl are brown. Here's the temp sensor

https://i.ytimg.com/vi/M_bITnAPp8Y/maxresdefault.jpg

Here's the VRO tank sensor that connects to a black wire that then exists the motor and goes to the VRO tank.

http://i28.tinypic.com/2nq7dhl.jpg

Should be another brown wire that goes to the VRO though another connector if my memory serves be correct.

A schematic would serve you well. This is from an 84 motor, but the VRO circuit should be the same or similar.

http://maxrules.com/graphics/omc/wiring/78-84_3-CYL_EL.jpg

D-

-

thediscusthrower

- Posts: 55

- Joined: Tue May 16, 2017 1:05 pm

- Location: Southern NJ

Re: 1996 Evinrude 70 hp: Alarm Horn

https://scontent-iad3-1.xx.fbcdn.net/v/ ... e=5A666AF5

https://scontent-iad3-1.xx.fbcdn.net/v/ ... e=5A84B93D

https://scontent-iad3-1.xx.fbcdn.net/v/ ... e=5A80E93D

Any clues based on these pics? Are these "sensors" just connected via male/female connectors OR the smaller version of the big red plug but in black? Are they terminal in nature or in-line?

https://scontent-iad3-1.xx.fbcdn.net/v/ ... e=5A84B93D

https://scontent-iad3-1.xx.fbcdn.net/v/ ... e=5A80E93D

Any clues based on these pics? Are these "sensors" just connected via male/female connectors OR the smaller version of the big red plug but in black? Are they terminal in nature or in-line?

Re: 1996 Evinrude 70 hp: Alarm Horn

Ok, your motor is the later design, so the schematic I shared is of no use. Find a shop manual with a schematic and start looking what they identify for sensor wiring. I've taken you as far as I can without being there.

D-

D-

Re: 1996 Evinrude 70 hp: Alarm Horn

The sensors are usually quite simple devices.

A temperature sensor threads into a boss in the cylinder head, and often has a small terminal post atop the sensor. A wire with TAN insulation connects to the terminal post.

There may be two engine temperature sensors. The wiring for one of the temperature sensors will also run over to the PowerPack. In these engines the engine spark timing is usually advanced when the engine temperature is low. The sensor switch on that sensor closes when the engine temperature gets to operating range. This signals to the Power Pack that the engine temperature is at normal operating level, and the Power Pack changes the spark timing. On small two-stroke-power-cycle engines the idle speed is very dependent on spark timing. A little advance in spark timing will increase engine idle speed. This lets the engine idle at a faster speed until it has warmed to operating temperature.

A second sensor, or perhaps a second switch built into the first sensor, will signal an over-heat condition. This will sound the alarm.

The oil reservoir tank level sensor is down in the oil reservoir tank, and the electrical lead usually comes up, out of the tank, and makes some sort of connection to the engine via a small electrical connector. I would expect the connector to be a two-pole connector, because the switch has to have both the alarm and the ground circuit carried out to it.

You need to carefully read the OPERATOR GUIDE for the engine. It will tell you what warnings are given and what conditions cause them. By reading the operating guide you can deduce the type and number of sensors.

As mentioned, the wire insulation for sensors will usually be TAN.

A temperature sensor threads into a boss in the cylinder head, and often has a small terminal post atop the sensor. A wire with TAN insulation connects to the terminal post.

There may be two engine temperature sensors. The wiring for one of the temperature sensors will also run over to the PowerPack. In these engines the engine spark timing is usually advanced when the engine temperature is low. The sensor switch on that sensor closes when the engine temperature gets to operating range. This signals to the Power Pack that the engine temperature is at normal operating level, and the Power Pack changes the spark timing. On small two-stroke-power-cycle engines the idle speed is very dependent on spark timing. A little advance in spark timing will increase engine idle speed. This lets the engine idle at a faster speed until it has warmed to operating temperature.

A second sensor, or perhaps a second switch built into the first sensor, will signal an over-heat condition. This will sound the alarm.

The oil reservoir tank level sensor is down in the oil reservoir tank, and the electrical lead usually comes up, out of the tank, and makes some sort of connection to the engine via a small electrical connector. I would expect the connector to be a two-pole connector, because the switch has to have both the alarm and the ground circuit carried out to it.

You need to carefully read the OPERATOR GUIDE for the engine. It will tell you what warnings are given and what conditions cause them. By reading the operating guide you can deduce the type and number of sensors.

As mentioned, the wire insulation for sensors will usually be TAN.

-

thediscusthrower

- Posts: 55

- Joined: Tue May 16, 2017 1:05 pm

- Location: Southern NJ

Re: 1996 Evinrude 70 hp: Alarm Horn

The word "sensors" is confusing in terms of boat motors vs. cars/trucks. On a truck, you would have a sensor say, screwed into an intake manifold, with a wire running to it. On this Evinrude, it's all disconnected via the harness, hence my learning curve. Took some time to process what's going on. This is brand new territory for me while you guys could probably do it in your sleep!

I have the following deciphered:

Low Oil Warning connector/sensor = (1) Black wire + (1) Tan wire w/black banding

No Oil/VRO Warning " = (1) Black +(1) Purple + (1) Tan + (1) Grey

Temperature Warning " = (1) Tan + (1) White w/black banding

Running out of daylight but I'm going to give it a try.

P.S. Thanks for all the help and getting me to this point!

Bob

I have the following deciphered:

Low Oil Warning connector/sensor = (1) Black wire + (1) Tan wire w/black banding

No Oil/VRO Warning " = (1) Black +(1) Purple + (1) Tan + (1) Grey

Temperature Warning " = (1) Tan + (1) White w/black banding

Running out of daylight but I'm going to give it a try.

P.S. Thanks for all the help and getting me to this point!

Bob

Last edited by thediscusthrower on Fri Oct 20, 2017 6:34 pm, edited 1 time in total.

-

thediscusthrower

- Posts: 55

- Joined: Tue May 16, 2017 1:05 pm

- Location: Southern NJ

Re: 1996 Evinrude 70 hp: Alarm Horn

BINGO! Low oil sensor going up to (or coming from) the reservoir.

https://scontent-iad3-1.xx.fbcdn.net/v/ ... e=5A695067

According to my mechanic at the local boat yard, he says this is some sort of engineering defect and in order to fix it, I have to purchase the entire unit. He told me not to worry about it, as long as I keep the tank full with oil (which I always do), it won't be a problem.

What do I do about the electrical/sensor connection though?

Process of elimination described by Jim worked like a charm, i.e., once I was able to find the wiring connectors.

Not bad for a beginner right? I still can't believe that the big red plug wasn't involved. Hard to believe with that corrosion level, especially on the one circuit.

https://scontent-iad3-1.xx.fbcdn.net/v/ ... e=5A695067

According to my mechanic at the local boat yard, he says this is some sort of engineering defect and in order to fix it, I have to purchase the entire unit. He told me not to worry about it, as long as I keep the tank full with oil (which I always do), it won't be a problem.

What do I do about the electrical/sensor connection though?

Process of elimination described by Jim worked like a charm, i.e., once I was able to find the wiring connectors.

Not bad for a beginner right? I still can't believe that the big red plug wasn't involved. Hard to believe with that corrosion level, especially on the one circuit.

Re: 1996 Evinrude 70 hp: Alarm Horn

If you found that disconnecting the LOW OIL SENSOR circuit shut off the CONTINUOUS ALERT TONE, then the sensor must be defective. The low oil sensor is NEVER supposed to produce a continuous alert tone; it is supposed to beep once every 20-seconds.

The low oil level sensor is not a simple switch. When the float in the tank reaches the alarm threshold, the sensor is supposed to produced a momentary closure of the TAN wire to ground, every 20 seconds. The sensor has some simple electronics to turn the continuous closure of the float switch into a momentary closure on the alarm TAN conductor. This means you can't just fix something mechanical about the float switch; you have to replace the sensor assembly to repair the bad electronics it contains.

The low oil level sensor is not a simple switch. When the float in the tank reaches the alarm threshold, the sensor is supposed to produced a momentary closure of the TAN wire to ground, every 20 seconds. The sensor has some simple electronics to turn the continuous closure of the float switch into a momentary closure on the alarm TAN conductor. This means you can't just fix something mechanical about the float switch; you have to replace the sensor assembly to repair the bad electronics it contains.

Re: 1996 Evinrude 70 hp: Alarm Horn

Similarly, on our 190 Nantucket we would get a warning of four-BEEPS every two minutes from the Mercury OPTI 150. I had to replace the engine oil tank because the magnetic float broke in the sealed tank.

DISCUS' should be very concerned about the red [Amphenol multi-pole] plug. If a wire in the plug is not making contact you might not get a warning signal that might alert you to a serious situation on your motor.

DISCUS' should be very concerned about the red [Amphenol multi-pole] plug. If a wire in the plug is not making contact you might not get a warning signal that might alert you to a serious situation on your motor.

Re: 1996 Evinrude 70 hp: Alarm Horn

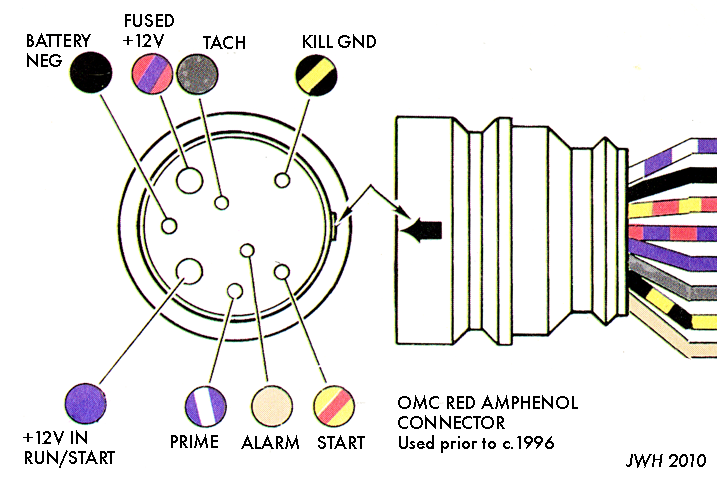

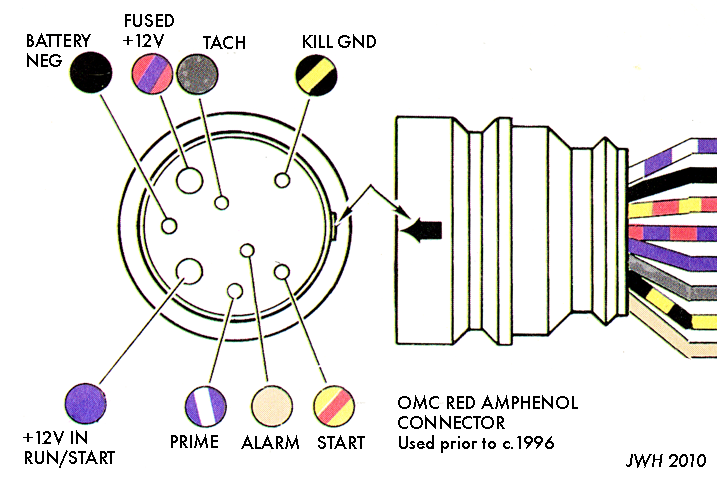

Regarding how to improve the connections in an electrical connector like the large, circular, red, rubber-body Amphenol multi-pole connector used by Evinrude on their engine electrical harnesses to connect to the remote controls until the introduction of the MWS system in c.1996:

The mating of these large rubber body connectors will be made much easier if you apply some alcohol to the rubber bodies of the two connectors. Wetting the rubber slightly with alcohol will allow the connectors to be mated with much less difficulty than if both are dry, and the alcohol evaporates away a few moments later. Do not use alcohol that is diluted in water; looking for isopropyl (rubbing) alcohol that is at least 70-percent alcohol.

Also, I would NEVER use a carbonated soda beverage as a contact cleaner for electrical contacts, except as a last resort in an emergency. The electrical contacts in the Evinrude Amphenol connector are silver-plated. You should be able to restore good conductivity to them by using a spray application of WD40, wetting the contacts, then shaking off the excess WD40. The engine shut-off circuit for the safety lanyard switch is one of the conductors in this contact; this circuit carries several hundred volts, so do not energize the circuit when the contacts are still wet with WD40. You just want a film of WD40 on the actual contact surfaces, not puddles of it in the connector housing. In a case of extreme corrosion of the electrical contacts, I would attempt to burnish the surfaces of the male contacts (pins) by careful wet-sanding with WD40 and extremely fine emery cloth.

Do not apply gobs of grease sold as dielectric grease to the contacts or the connector body. The connector body will make its own tight seal, rubber on rubber, and does not need grease. Use alcohol as I described above to help mate the connector. Please note that dielectric grease is an excellent insulator; it has no conductivity. It cannot improve electrical current flow. It should never be applied to any electrical contact. Dielectric grease is only used with some connectors as a lubricant and sealant for the connector body surfaces that have to contact other connector body surfaces. A very thin coating of grease is sometimes recommended for certain connectors. It should not be applied directly to any electrical contacts.

In the case of the connector shown in linked images (above), that connector shows a greenish-blue corrosion that is typical for oxidized copper. The connector is in bad condition. It appears that there is a male contact missing.

The individual contacts in the connector body can be removed. They load into the connector body from the rear. Generally a specialized small tool is used to aid in removal of such contacts. The tool can take the form of a circular tube that is pushed over the male contact, into the body of the connector, where it pushed down on the latching spring of the contact, allowing the contact to be pulled out from the rear. Check with an older OMC dealer for advice on how to service the connector.

It is also possible to eliminate the connector completely, and just fashion your own interconnection for the circuits involved. You could use something as simple as single-conductor connectors to connect the several circuits individually to their appropriate other circuit. For example, you could use something like the ones seen at this resource:

http://www.cycleterminal.com/bullet-connectors.html

Or, you could buy all new terminals for the Amphenol connector, and recreate the original connector. I don't know of an aftermarket source for those connector parts. Check with your OMC dealer to see if the parts are still available from Evinrude. Or you might find an old engine that has been scrapped for parts and harvest its electrical harness.

I illustrate the large circular red rubber-body Amphenol connector in an article in REFERENCE that discusses ignition switch wiring. Here is the illustration from that article:

The mating of these large rubber body connectors will be made much easier if you apply some alcohol to the rubber bodies of the two connectors. Wetting the rubber slightly with alcohol will allow the connectors to be mated with much less difficulty than if both are dry, and the alcohol evaporates away a few moments later. Do not use alcohol that is diluted in water; looking for isopropyl (rubbing) alcohol that is at least 70-percent alcohol.

Also, I would NEVER use a carbonated soda beverage as a contact cleaner for electrical contacts, except as a last resort in an emergency. The electrical contacts in the Evinrude Amphenol connector are silver-plated. You should be able to restore good conductivity to them by using a spray application of WD40, wetting the contacts, then shaking off the excess WD40. The engine shut-off circuit for the safety lanyard switch is one of the conductors in this contact; this circuit carries several hundred volts, so do not energize the circuit when the contacts are still wet with WD40. You just want a film of WD40 on the actual contact surfaces, not puddles of it in the connector housing. In a case of extreme corrosion of the electrical contacts, I would attempt to burnish the surfaces of the male contacts (pins) by careful wet-sanding with WD40 and extremely fine emery cloth.

Do not apply gobs of grease sold as dielectric grease to the contacts or the connector body. The connector body will make its own tight seal, rubber on rubber, and does not need grease. Use alcohol as I described above to help mate the connector. Please note that dielectric grease is an excellent insulator; it has no conductivity. It cannot improve electrical current flow. It should never be applied to any electrical contact. Dielectric grease is only used with some connectors as a lubricant and sealant for the connector body surfaces that have to contact other connector body surfaces. A very thin coating of grease is sometimes recommended for certain connectors. It should not be applied directly to any electrical contacts.

In the case of the connector shown in linked images (above), that connector shows a greenish-blue corrosion that is typical for oxidized copper. The connector is in bad condition. It appears that there is a male contact missing.

The individual contacts in the connector body can be removed. They load into the connector body from the rear. Generally a specialized small tool is used to aid in removal of such contacts. The tool can take the form of a circular tube that is pushed over the male contact, into the body of the connector, where it pushed down on the latching spring of the contact, allowing the contact to be pulled out from the rear. Check with an older OMC dealer for advice on how to service the connector.

It is also possible to eliminate the connector completely, and just fashion your own interconnection for the circuits involved. You could use something as simple as single-conductor connectors to connect the several circuits individually to their appropriate other circuit. For example, you could use something like the ones seen at this resource:

http://www.cycleterminal.com/bullet-connectors.html

Or, you could buy all new terminals for the Amphenol connector, and recreate the original connector. I don't know of an aftermarket source for those connector parts. Check with your OMC dealer to see if the parts are still available from Evinrude. Or you might find an old engine that has been scrapped for parts and harvest its electrical harness.

I illustrate the large circular red rubber-body Amphenol connector in an article in REFERENCE that discusses ignition switch wiring. Here is the illustration from that article:

-

thediscusthrower

- Posts: 55

- Joined: Tue May 16, 2017 1:05 pm

- Location: Southern NJ

Re: 1996 Evinrude 70 hp: Alarm Horn

InVision wrote:DISCUS' should be very concerned about the red [Amphenol multi-pole] plug. If a wire in the plug is not making contact you might not get a warning signal that might alert you to a serious situation on your motor.

I cleaned the big, red plug up with PB Blaster (which pretty much dissolved the corrosion) along with a wire brush, followed by "rinsing" with Brake Cleaner to dry things up. I only had one circuit which was determined to be defective post-cleaning: the male contact had corroded to the point where it had broken off inside the female receptor, but I was able to remove it. That was the red wire with violet stripe. I pushed the lead back out of the plug, reinstalled a new male end, and persuaded it back into the plug in its original position. I added some dielectric grease inside of the plug (i.e., on the female side, as well as along the point where they join together to prevent saltwater intrusion).

The other sensors, the no oil and water temperature, turned out to be fine in terms of the testing protocol defined by Jim.

I WANT TO SINCERELY THANK THOSE IN THE THREAD WHO WERE WILLING TO HELP ME GET THIS DONE!!! IT WAS A LEARNING EXPERIENCE WHICH WILL BENEFIT ME NOT ONLY IN THE SHORT TERM, BUT LONGER TERM.

Bob

Re: 1996 Evinrude 70 hp: Alarm Horn

Here are the BEFORE pictures:

DId you take any AFTER pictures?

DId you take any AFTER pictures?

Re: 1996 Evinrude 70 hp: Alarm Horn

You can identify most of the circuit functions in the Evinrude wiring by the color of the wire insulation. Here is a good reference for wire insulation color coding for OMC engines:

Marine Wiring Color Codes

http://continuouswave.com/whaler/reference/wireColorCode.html#OMC

Note that in just about all electrical literature, a wire color of a red-blue hue is usually described as violet. The color name "purple" is the name of a crayon color in a children's box of Crayola Crayons, but it is used historically in the service literature published by OMC for their service technicians going back many decades.

Marine Wiring Color Codes

http://continuouswave.com/whaler/reference/wireColorCode.html#OMC

Note that in just about all electrical literature, a wire color of a red-blue hue is usually described as violet. The color name "purple" is the name of a crayon color in a children's box of Crayola Crayons, but it is used historically in the service literature published by OMC for their service technicians going back many decades.

-

thediscusthrower

- Posts: 55

- Joined: Tue May 16, 2017 1:05 pm

- Location: Southern NJ

Re: 1996 Evinrude 70 hp: Alarm Horn

jimh wrote:Do not apply gobs of grease sold as dielectric grease to the contacts or the connector body. The connector body will make its own tight seal, rubber on rubber, and does not need grease. Use alcohol as I described above to help mate the connector. Please note that dielectric grease is an excellent insulator; it has no conductivity. It cannot improve electrical current flow. It should never be applied to any electrical contact. Dielectric grease is only used with some connectors as a lubricant and sealant for the connector body surfaces that have to contact other connector body surfaces. A very thin coating of grease is sometimes recommended for certain connectors. It should not be applied directly to any electrical contacts.

I've always applied a small "dab" of dielectric grease to electrical connections in order to prevent corrosion and have never had any problems. Are you suggesting that I re-clean the Amphenol plug (i.e., to remove the dielectric grease) and re-install? Everything appears to be operating correctly now.

Reason for asking is if the connector body makes it's own seal, then this kind of contradicts the evidence as noted by the photographs (i.e., oxidative corrosion) right?

Bob

-

thediscusthrower

- Posts: 55

- Joined: Tue May 16, 2017 1:05 pm

- Location: Southern NJ

Re: 1996 Evinrude 70 hp: Alarm Horn

jimh wrote:DId you take any AFTER pictures?

No. Just cleaned up as described previously.

Re: 1996 Evinrude 70 hp: Alarm Horn

I just want to note that Jim's posts of plug illustration is invaluable !!

Wealth of info.

M

Wealth of info.

M

Re: 1996 Evinrude 70 hp: Alarm Horn

In the case of a 21-year-old rubber-body connection, a bit of dielectric grease might be helpful in sealing the connector so water cannot get into the interior contacts. After 21-years perhaps the rubber has taken a set or is not as pliable as when it was first made in 1996. I don't have a problem with dielectric grease as a lubricant and sealant for the connector's non-conductive elements. The grease does nothing to help CONDUCT electricity. In fact, the grease is about the best INSULATOR you can get and that is what it is designed to do: prevent electrical current from flowing. No one ever puts dielectric grease on the electrical contacts where current is supposed to flow--except boaters who read advice from other boaters. Grease prevents flow of current. That is its mission: stop the flow of current.

-

thediscusthrower

- Posts: 55

- Joined: Tue May 16, 2017 1:05 pm

- Location: Southern NJ

Re: 1996 Evinrude 70 hp: Alarm Horn

jimh wrote:In the case of a 21-year-old rubber-body connection, a bit of dielectric grease might be helpful in sealing the connector so water cannot get into the interior contacts. After 21-years perhaps the rubber has taken a set or is not as pliable as when it was first made in 1996. I don't have a problem with dielectric grease as a lubricant and sealant for the connector's non-conductive elements. The grease does nothing to help CONDUCT electricity. In fact, the grease is about the best INSULATOR you can get and that is what it is designed to do: prevent electrical current from flowing. No one ever puts dielectric grease on the electrical contacts where current is supposed to flow--except boaters who read advice from other boaters. Grease prevents flow of current. That is its mission: stop the flow of current.

Actually, it's remarkably pliable for its age. Surprised me too.

So what you are saying [Jim] is to basically clean-up and mate your metal-to-metal electrical connection, then place the dielectric grease on the surface of that connection (e.g., battery terminal) OR in the case of a connective device (e.g., the big red plug) around the rim where the two pieces join together to prevent saltwater intrusion and INSULATE it, and others, from future corrosion? In that way, you maximize the electrical connection on a clean, contact(s) surface AND protect from future corrosion via the dielectric grease.

P.S. I will heed your advise and pull the plug apart and remove the dielectric grease from the terminals as suggested.

Bob

Re: 1996 Evinrude 70 hp: Alarm Horn

Bob--if the connection is working now, I'd leave it alone.

The boating-electricity-theorists who recommend smearing INSULATING dielectric grease directly on conductive electrical contacts used on boats have a theory that the INSULATING grease is completely wiped away when the contacts mate, and the INSULATING grease has no effect on the electrical resistance of the contacts. It's a good theory, but I prefer to go with mating electrical contacts that are clean, dry, and free from any residue of anything. I don't think the grease is completely removed. I know how hard grease can be to get off my hands. Why would grease just come off a rather small electrical contact so much easier?

I think the boating-electricity-theorists are confused by the use of a CONDUCTIVE paste that is very often used when making electrical contacts, particularly when one of the conductors is made from aluminum. For many decades a CONDUCTIVE paste made by the Burndy Electrical company and called Penetrox-A has been in widespread use with aluminum conductors to improved the long-term conductivity of aluminum-to-aluminum and aluminum-to-other metal contacts. This is because aluminum oxide is generally a poor conductor, and using a conductive paste keeps air away from the aluminum.

In modern electrical connectors, the actual contacts are usually made from materials like copper, tin, silver, or gold, and aluminum is never used as a contact material. Copper Oxide is not a conductor, so when a copper conductor comes in contact with air or water, the result is formation of copper oxide that does not conduct. Tinning of copper wire is done to prevent formation of copper oxides.

Silver oxide is a conductor, and that is why many contacts are made with silver instead of copper. Even if silver oxidizes it is still conductive.

Gold does not oxidize.

It is quite common to see advice from MANUFACTURERS of marine products with electrical connectors that suggests a thin coating of dielectric grease should be applied to the seal material of the body of an electrical connector. The advice is often accompanied by advice to NOT apply the grease to the actual contacts.

The boating-electricity-theorists who recommend smearing INSULATING dielectric grease directly on conductive electrical contacts used on boats have a theory that the INSULATING grease is completely wiped away when the contacts mate, and the INSULATING grease has no effect on the electrical resistance of the contacts. It's a good theory, but I prefer to go with mating electrical contacts that are clean, dry, and free from any residue of anything. I don't think the grease is completely removed. I know how hard grease can be to get off my hands. Why would grease just come off a rather small electrical contact so much easier?

I think the boating-electricity-theorists are confused by the use of a CONDUCTIVE paste that is very often used when making electrical contacts, particularly when one of the conductors is made from aluminum. For many decades a CONDUCTIVE paste made by the Burndy Electrical company and called Penetrox-A has been in widespread use with aluminum conductors to improved the long-term conductivity of aluminum-to-aluminum and aluminum-to-other metal contacts. This is because aluminum oxide is generally a poor conductor, and using a conductive paste keeps air away from the aluminum.

In modern electrical connectors, the actual contacts are usually made from materials like copper, tin, silver, or gold, and aluminum is never used as a contact material. Copper Oxide is not a conductor, so when a copper conductor comes in contact with air or water, the result is formation of copper oxide that does not conduct. Tinning of copper wire is done to prevent formation of copper oxides.

Silver oxide is a conductor, and that is why many contacts are made with silver instead of copper. Even if silver oxidizes it is still conductive.

Gold does not oxidize.

It is quite common to see advice from MANUFACTURERS of marine products with electrical connectors that suggests a thin coating of dielectric grease should be applied to the seal material of the body of an electrical connector. The advice is often accompanied by advice to NOT apply the grease to the actual contacts.

-

thediscusthrower

- Posts: 55

- Joined: Tue May 16, 2017 1:05 pm

- Location: Southern NJ

Re: 1996 Evinrude 70 hp: Alarm Horn

I cleaned it up as I said I would do. I prefer to do things the right way and I was apparently not following suit.

I took the boat out on the Delaware River for a shake-down ride TODAY. Everything went well. Just a couple of minor problems regarding a Sea Dog plug-in power supply for my Raymarine GPS unit AND tachometer not working. I will seek help for the latter in a new post.

Bob

I took the boat out on the Delaware River for a shake-down ride TODAY. Everything went well. Just a couple of minor problems regarding a Sea Dog plug-in power supply for my Raymarine GPS unit AND tachometer not working. I will seek help for the latter in a new post.

Bob

Re: 1996 Evinrude 70 hp: Alarm Horn

The 1996 evinrude 70hp engines that I have seen do not have the RED harness plug. MWS began in1996. What is the model and serial number for your engine?

-

thediscusthrower

- Posts: 55

- Joined: Tue May 16, 2017 1:05 pm

- Location: Southern NJ

Re: 1996 Evinrude 70 hp: Alarm Horn

Model # E70EDTLA

Don't know the serial # off hand.

Bob

Don't know the serial # off hand.

Bob

Re: 1996 Evinrude 70 hp: Alarm Horn

Hi Bob, I do not see anywhere at Evinrude or any other parts source that Model number E70EDTLA . Could you post a picture of the model/serial number tag that is attached to your engine at some point?

The MWS wiring system from 1996 forward uses three harness plugs at the rear of the engine. Would be interesting to see.

Thanks Chuck

The MWS wiring system from 1996 forward uses three harness plugs at the rear of the engine. Would be interesting to see.

Thanks Chuck

-

thediscusthrower

- Posts: 55

- Joined: Tue May 16, 2017 1:05 pm

- Location: Southern NJ

Re: 1996 Evinrude 70 hp: Alarm Horn

conch wrote:Hi Bob, I do not see anywhere at Evinrude or any other parts source that Model number E70EDTLA . Could you post a picture of the model/serial number tag that is attached to your engine at some point?

The MWS wiring system from 1996 forward uses three harness plugs at the rear of the engine. Would be interesting to see.

Thanks Chuck

My boat is a 1995, so I assume that the motor is the same. That said, assumptions can sometimes turn out to be wrong. There is a tag on the steering column part of the motor. I painted over it for protective purposes. My question: is the tag "stamped/embossed" with the model # or painted?

I went back into my e-mails at the time I bought it and I referenced E70TLEDA. I have the 1995 50-70hp 3 Cyl. Engine Manual. It lists the following model numbers for Evinrude:

E70ELED

E70TLED

E70TXED

Maybe the "A" suffix represents the first part of the year?

It does not operate off of the System [Check] gauge here as pictured at: download/file.php?id=2409

Bob

Last edited by thediscusthrower on Wed Nov 01, 2017 3:10 pm, edited 1 time in total.

Re: 1996 Evinrude 70 hp: Alarm Horn

In OMC model designators, the last alphabetic character usually represent the production sun sequence, and an "A" would be interpreted as the first production run. The "ED" designators refer to the model year (now production year) with E=9 and D=6, this [19]96. The secret coding (used after c.1979) is

1 2 3 4 5 6 7 8 9 0

I N T R O D U C E S

The initial "E" is for Evinrude; the "70" is the horsepower rating; the "T" means trim and tilt with electric starting; the "L" means long shaft or 20-inch shaft.

Summary: an OMC engine with model designator E70TLEDA is:

E--an Evinrude

70--70-HP

T--electric starting engine with power trim and tilt

L--20-inch shaft legnth

ED--a 1996 model

A--made in the "A" production run

For more help with OMC and later BRP model code deciphering, see the thread on that topic at

viewtopic.php?f=6&t=2829#p16123

1 2 3 4 5 6 7 8 9 0

I N T R O D U C E S

The initial "E" is for Evinrude; the "70" is the horsepower rating; the "T" means trim and tilt with electric starting; the "L" means long shaft or 20-inch shaft.

Summary: an OMC engine with model designator E70TLEDA is:

E--an Evinrude

70--70-HP

T--electric starting engine with power trim and tilt

L--20-inch shaft legnth

ED--a 1996 model

A--made in the "A" production run

For more help with OMC and later BRP model code deciphering, see the thread on that topic at

viewtopic.php?f=6&t=2829#p16123

Re: 1996 Evinrude 70 hp: Alarm Horn

thediscusthrower wrote:It [i.e., the engine we have been discussing for a few weeks and is now said t be a E70TLDA model] does not operate off of the System [Check] gauge...

According the the drawings on the Evinrude website, an Evinrude engine with model designator E70TLEDA uses the MWS wiring system; it should not have a large red rubber Amphenol multi-pin connector in the wiring harness.

If you engine has that connector, I would have serious doubt that it is an E70TLEDA engine.

The Evinrude website shows that a 1995 model 70 uses the older style, large, red, rubber, Amphenol connector.

Re: 1996 Evinrude 70 hp: Alarm Horn

conch wrote:I do not see anywhere at Evinrude or any other parts source that Model number E70EDTLA

Yes, I think that number was bogus. Now we seem to be talking about an E70TLEDA engine, but I am now suspect of that model designation because the specified engine should have the modern MWS wiring harness, not the older large, round, red, rubber, Amphenol connector harness. Something is still suspect about the E70TLEDA model designator for the engine we have been discussing. It does not fit the actual wiring harness shown for the engine.