190 Outrage Trolling Motor Installation

190 Outrage Trolling Motor Installation

I may install a trolling motor at the bow of a 190 OUTRAGE called an iPilot 24-Volt 72-inch shaft.

Give me advice on the installation.

Give me advice on the installation.

Re: 190 Outrage Trolling Motor Installation

Use stainless toggle bolts:

https://www.wholesalemarine.com/garelick-stainless-steel-toggle-bolt-anchors.html

Trolling Motor install write-up. Apologies for the broken formatting. Includes product information.

https://drive.google.com/file/d/1_K_8EO6kbk7gu-EVshie9_6A7U1Sl50G/view?usp=sharing

(edit - fixed sharing permissions)

https://www.wholesalemarine.com/garelick-stainless-steel-toggle-bolt-anchors.html

Trolling Motor install write-up. Apologies for the broken formatting. Includes product information.

https://drive.google.com/file/d/1_K_8EO6kbk7gu-EVshie9_6A7U1Sl50G/view?usp=sharing

(edit - fixed sharing permissions)

1992 Outrage 17

2019 E-TEC 90

2018 LoadRite 18280096VT

Member since 2003

2019 E-TEC 90

2018 LoadRite 18280096VT

Member since 2003

Re: 190 Outrage Trolling Motor Installation

I was doing some research on installing a similar trolling motor on my 2014 Montauk 170. I came across the toggle bolt idea and was wondering if the foam beneath the deck would create a problem when the toggles deploy.

Q1: should I assume from Phil's post that the toggle bolts have been used successfully and the toggles must cut through the foam when being deployed under the deck?

Give me advice [about risk to the foam in a Unibond hull from] the use [of toggle boats to mount a trolling motor at the bow of a 170 MONTAUK].

Q1: should I assume from Phil's post that the toggle bolts have been used successfully and the toggles must cut through the foam when being deployed under the deck?

Give me advice [about risk to the foam in a Unibond hull from] the use [of toggle boats to mount a trolling motor at the bow of a 170 MONTAUK].

Re: 190 Outrage Trolling Motor Installation

The most secure mounting for a trolling motor on the bow will be to through-bolt the mounting base to the hull when possible.

Re: 190 Outrage Trolling Motor Installation

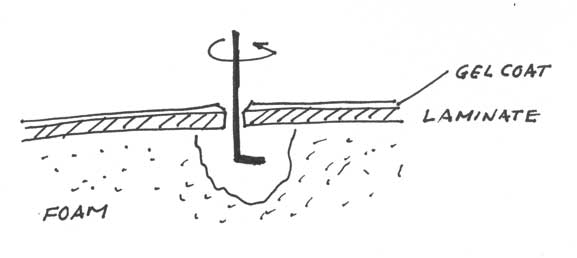

If you have problems inserting the toggle into the hole, use a small allen wrench in a drill (short end in chuck) and create a small void.

In some installations it is possible to through bolt one or two of the mounting fasteners.

Note you should use sealant (Boat Life) on the toggle, through bolts as well as the mount to ensure a watertight fit.

In some installations it is possible to through bolt one or two of the mounting fasteners.

Note you should use sealant (Boat Life) on the toggle, through bolts as well as the mount to ensure a watertight fit.

1992 Outrage 17

2019 E-TEC 90

2018 LoadRite 18280096VT

Member since 2003

2019 E-TEC 90

2018 LoadRite 18280096VT

Member since 2003

Re: 190 Outrage Trolling Motor Installation

The sketch below illustrates the use of an Allen wrench to abrade and remove foam under the laminate to create an air pocket:

Fig. 1. Use a small L-shaped tool as a crude auger to cut away and remove foam under the laminate layer, creating a void or pocket. Into this void a mixture of epoxy and filler can be introduced to create additional material for retaining a screw fastener.

Source: https://continuouswave.com/forum/viewto ... 224#p18406

Fig. 1. Use a small L-shaped tool as a crude auger to cut away and remove foam under the laminate layer, creating a void or pocket. Into this void a mixture of epoxy and filler can be introduced to create additional material for retaining a screw fastener.

Source: https://continuouswave.com/forum/viewto ... 224#p18406

Re: 190 Outrage Trolling Motor Installation

A lot of good and helpful information has been posted. Thanks.

Q2: have batteries for an electric trolling motor EVER been put in the anchor locker of a 190 OUTRAGE?

The anchor locker of a 190 OUTRAGE seems to have enough room. A leveling bottom plate would be needed.

Q2: have batteries for an electric trolling motor EVER been put in the anchor locker of a 190 OUTRAGE?

The anchor locker of a 190 OUTRAGE seems to have enough room. A leveling bottom plate would be needed.

Re: 190 Outrage Trolling Motor Installation

The anchor locker in the front of the boat would cause the batteries to be subject to more pounding from the boat encountering waves and wakes compared to batteries located further aft.

Re: 190 Outrage Trolling Motor Installation

Agree with Mark.

Go for console or front cooler.

Go for console or front cooler.

1992 Outrage 17

2019 E-TEC 90

2018 LoadRite 18280096VT

Member since 2003

2019 E-TEC 90

2018 LoadRite 18280096VT

Member since 2003

Re: 190 Outrage Trolling Motor Installation

I have been talking with a boat mechanic who may install the electric motor for me. He doesn't want to use the toggle bolts since he has tried them in the past and they came loose ("wallowed out") over time. He prefers to cut an access hole, dig out some foam and then through bolt the mount with normal bolts and nuts. I'd really like to minimize the holes and foam removal.

Q3: has anyone EVER had experience with these toggle bolts on a electric motor mount?

Q4: can anyone verify toggle boats work?

Q3: has anyone EVER had experience with these toggle bolts on a electric motor mount?

Q4: can anyone verify toggle boats work?

Re: 190 Outrage Trolling Motor Installation

Please do not do this, [that is, do not cut a hole and dig out foam before through-bolting a trolling motor at the bow].

Q5: have you checked the backing diagram to see if there is already reinforcement in the bow?

In specific areas there is phenolic (like starboard) material embedded in the fiberglass to provide backing reinforcement.

Here is the diagram for the 2010 model year Outrage 190.

Ref: https://www.bostonwhaler.com/content/dam/boston-whaler/technical/resources/190-Outrage-Wood-Locating-Diagrams-2010.pdf

Q6: what model year is your boat?

If there isn't any reinforcement, there is another method, albeit not as straight forward as toggle bolts that is recommended. It is referred to as the "hockey puck" method. This method is obsolete and has been replaced with the stainless toggle bolts.

At each fastener location, drill a 0.33-inch hole, dig out the foam with an Allen wrench. Tape off the deck three inches around the hole. Insert Gorilla Glue, an expanding polyester based epoxy glue. Allow it to expand. Fill again till it overflows out of the hole. Let cure. Trim excess.

This is the puck. Tap for the fastener.

Q5: have you checked the backing diagram to see if there is already reinforcement in the bow?

In specific areas there is phenolic (like starboard) material embedded in the fiberglass to provide backing reinforcement.

Here is the diagram for the 2010 model year Outrage 190.

Ref: https://www.bostonwhaler.com/content/dam/boston-whaler/technical/resources/190-Outrage-Wood-Locating-Diagrams-2010.pdf

Q6: what model year is your boat?

If there isn't any reinforcement, there is another method, albeit not as straight forward as toggle bolts that is recommended. It is referred to as the "hockey puck" method. This method is obsolete and has been replaced with the stainless toggle bolts.

At each fastener location, drill a 0.33-inch hole, dig out the foam with an Allen wrench. Tape off the deck three inches around the hole. Insert Gorilla Glue, an expanding polyester based epoxy glue. Allow it to expand. Fill again till it overflows out of the hole. Let cure. Trim excess.

This is the puck. Tap for the fastener.

1992 Outrage 17

2019 E-TEC 90

2018 LoadRite 18280096VT

Member since 2003

2019 E-TEC 90

2018 LoadRite 18280096VT

Member since 2003

Re: 190 Outrage Trolling Motor Installation

The most reasonable answer to your question that wants to know if at any time in the history of a 190 OUTRAGE has a battery been put into the anchor locker is NO, NEVER.jwaters58 wrote:Q2: have batteries for an electric trolling motor EVER been put in the anchor locker of a 190 OUTRAGE?

Putting a battery in the anchor locker is probably the absolutely WORST PLACE on the entire boat for that battery.

Re: 190 Outrage Trolling Motor Installation

Phil, thanks for the above drawing showing the phenolic reinforcement. My boat is a 2007. Those locations probably have not changed.

Q7: would there be any change of opinions if I used a gel battery in the anchor locker?

I will consider putting the batteries in the cooler if necessary. I am rarely accused of being [obsessively preoccupied by inconsequential elements,] but I really [do] not like anything in the [cockpit deck] of my [OUTRAGE] boat.

Q7: would there be any change of opinions if I used a gel battery in the anchor locker?

I will consider putting the batteries in the cooler if necessary. I am rarely accused of being [obsessively preoccupied by inconsequential elements,] but I really [do] not like anything in the [cockpit deck] of my [OUTRAGE] boat.

Re: 190 Outrage Trolling Motor Installation

This is the same drawing and has a date of 2005:

There were very few hull changes in this model.

There were very few hull changes in this model.

1992 Outrage 17

2019 E-TEC 90

2018 LoadRite 18280096VT

Member since 2003

2019 E-TEC 90

2018 LoadRite 18280096VT

Member since 2003

Re: 190 Outrage Trolling Motor Installation

NO.jwaters58 wrote:Q7: would there be any change of opinions if I used a gel battery in the anchor locker?

An on deck cooler is not a good place for batteries. Two large batteries to run a 24-Volt trolling motor will weigh about 150-lbs. That weight needs to be securely tied down and fastened to the deck. It should be near or on the hull centerline and amidships or aft of amidships.jwaters58 wrote: I will consider [installing] the batteries in the cooler if necessary.

Re: 190 Outrage Trolling Motor Installation

On Amazon you can buy a 100-Ampere-hour LiFePO4 12-Volt battery that weighs 24-lbs for $300. Two of those batteries could be placed in a cooler, using plywood cut to fit the bottom inside of the cooler to spread the load. Add a connector on the cooler to plug-in the trolling motor. With decent hold down for the cooler that should be okay.

I have 50-lbs of ice in my cooler all the time, and the cooler stays put even in rough conditions.

I have 50-lbs of ice in my cooler all the time, and the cooler stays put even in rough conditions.

Re: 190 Outrage Trolling Motor Installation

MARK's suggestion to use LiFePO4 batteries to save weight is a good idea, but I think the costs will be higher. First, I would NOT buy the batteries on Amazon from a no-name seller. There is a lot of made-in-China junk being sold these days, often with very poor internal construction, and often built with used cells with reduced capacity.

A 12-Volt 100-Ampere-hour LiFePO4 battery from a prominent brand like BATTLE BORN will cost a lot more, about $875, and weighs 31-lbs. Compare at

https://battlebornbatteries.com/product ... e-battery/

Second, you will also need a modern battery charger that can specifically re-charge LiFePO4 batteries. I would not plan to use the outboard engine as a charging source. An LiFePO4 battery will have an internal battery manage system that can instantly disconnect the battery from the charging current if there is any problem; such a disconnect from an outboard engine charging circuit would most likely cause harm to the outboard engine alternator.

Two of those batteries will weigh 62-lbs. Add the cost of a charger, taxes, and shipping, and you will be spending about $2,000.

A good source for reviews of LiFePO4 batteries is from Will Prowse. He actually disassembles the batteries he tests, inspects their construction, and generally finds many brand should be avoided. He has a channel on youTube. Browse his battery tear-down presentations at

https://www.youtube.com/playlist?list=PL7bvIB2TPsCjs5Fol7oDwE0k40bpXZBQs

A 12-Volt 100-Ampere-hour LiFePO4 battery from a prominent brand like BATTLE BORN will cost a lot more, about $875, and weighs 31-lbs. Compare at

https://battlebornbatteries.com/product ... e-battery/

Second, you will also need a modern battery charger that can specifically re-charge LiFePO4 batteries. I would not plan to use the outboard engine as a charging source. An LiFePO4 battery will have an internal battery manage system that can instantly disconnect the battery from the charging current if there is any problem; such a disconnect from an outboard engine charging circuit would most likely cause harm to the outboard engine alternator.

Two of those batteries will weigh 62-lbs. Add the cost of a charger, taxes, and shipping, and you will be spending about $2,000.

A good source for reviews of LiFePO4 batteries is from Will Prowse. He actually disassembles the batteries he tests, inspects their construction, and generally finds many brand should be avoided. He has a channel on youTube. Browse his battery tear-down presentations at

https://www.youtube.com/playlist?list=PL7bvIB2TPsCjs5Fol7oDwE0k40bpXZBQs

Re: 190 Outrage Trolling Motor Installation

Thanks Phil for the information about using toggle bolts.

I have a 2014 Montauk 170. My mechanic was proposing cutting out foam in the bow near the motor mount location. The 170 does have phenolic reinforcement in the bow.

So now I have three opinions on how to mount the electric motor. One from my mechanic that wants to cut a hole and install an access hatch so that he can remove foam and through bolt the mount. Two, the toggle bolts through the phenolic reinforcement. Three, from local BW dealer who wants to simply drill holes and install machine screws with no backing.

The toggle bolts seem to make the most sense to me. Before I go that route I hope to hear from other owners that can attest to the longevity of that method or another that stands the test of time.

I have a 2014 Montauk 170. My mechanic was proposing cutting out foam in the bow near the motor mount location. The 170 does have phenolic reinforcement in the bow.

So now I have three opinions on how to mount the electric motor. One from my mechanic that wants to cut a hole and install an access hatch so that he can remove foam and through bolt the mount. Two, the toggle bolts through the phenolic reinforcement. Three, from local BW dealer who wants to simply drill holes and install machine screws with no backing.

The toggle bolts seem to make the most sense to me. Before I go that route I hope to hear from other owners that can attest to the longevity of that method or another that stands the test of time.

Re: 190 Outrage Trolling Motor Installation

If you drill in an area that has phenolic backing, you do not need a toggle bolt. The backing is what adds the necessary strength. A machine screw is recommended.

The toggle bolt or "hockey puck" is only for locations where there is no embedded backing.

I am not sure why you would want more input.

Jim has 23+ years experience owning a whaler as well as creating and administering the most respected technical website dedicated to Boston Whalers in the world.

I have 15 years experience an an owner and moderator of more than one Boston Whaler owner website.

Then again, its your call.

The toggle bolt or "hockey puck" is only for locations where there is no embedded backing.

I am not sure why you would want more input.

Jim has 23+ years experience owning a whaler as well as creating and administering the most respected technical website dedicated to Boston Whalers in the world.

I have 15 years experience an an owner and moderator of more than one Boston Whaler owner website.

Then again, its your call.

1992 Outrage 17

2019 E-TEC 90

2018 LoadRite 18280096VT

Member since 2003

2019 E-TEC 90

2018 LoadRite 18280096VT

Member since 2003

Re: 190 Outrage Trolling Motor Installation

The 100-Ampere-hour LiFePO4 batteries I bought on Amazon from Chins weigh 24.5-lbs and now cost only $300. Their build quality was good according to Will Prowse.

I do not charge them with my outboard.

I bought a two bank charger that has a Lithium setting.

I was willing to take the gamble on the Chinese LiFePO4 batteries to save weight over lead-acid batteries and money compared to top tier LiFePO4 batteries. So far I am very pleased with the decision. Only time will tell.

I do not charge them with my outboard.

I bought a two bank charger that has a Lithium setting.

I was willing to take the gamble on the Chinese LiFePO4 batteries to save weight over lead-acid batteries and money compared to top tier LiFePO4 batteries. So far I am very pleased with the decision. Only time will tell.

Last edited by MarkCz on Mon Jan 09, 2023 5:00 pm, edited 1 time in total.

Re: 190 Outrage Trolling Motor Installation

Perhaps some clarification is needed about using embedded materials in a Unibond hull that are listed as being made of phenolic material.

Phenolic sheet or plate material used by Boston Whaler as an embedded reinforcement material in a Unibond hull can be tapped and threaded to hold a machine screw. Fastening to an embedded plate that has a tapped hole with a machine screw generally results in a strong fastening, as long as the threaded hole in the embedded material was properly made, that is, the proper size pilot hole was made for the tap that was used, resulting in properly cut threads in the hole. The thickness of the phenolic sheet or plate will affect the holding power of the machine screw fastener.

Using a phenolic sheet or plate to receive the machine screw instead of using an aluminum plate avoids the problem with galvanic corrosion due to dissimilar metals. In some instances on Unibond-hull boats with embedded aluminum as the reinforcement, the stainless steel fasteners and the aluminum plate become corroded and bonded together, and removal of the fasteners becomes extremely difficult, should the need ever arise.

Phenolic sheet or plate material used by Boston Whaler as an embedded reinforcement material in a Unibond hull can be tapped and threaded to hold a machine screw. Fastening to an embedded plate that has a tapped hole with a machine screw generally results in a strong fastening, as long as the threaded hole in the embedded material was properly made, that is, the proper size pilot hole was made for the tap that was used, resulting in properly cut threads in the hole. The thickness of the phenolic sheet or plate will affect the holding power of the machine screw fastener.

Using a phenolic sheet or plate to receive the machine screw instead of using an aluminum plate avoids the problem with galvanic corrosion due to dissimilar metals. In some instances on Unibond-hull boats with embedded aluminum as the reinforcement, the stainless steel fasteners and the aluminum plate become corroded and bonded together, and removal of the fasteners becomes extremely difficult, should the need ever arise.

Re: 190 Outrage Trolling Motor Installation

A Will Prowse endorsement is the seal of approval for me.MarkCz wrote:The 100-Ampere-hour LiFePO4 batteries I bought weigh 24.5-lbs and now cost only $300. Their build quality was good according to Will Prowse.

You might mention the particular brand of LiFePO4 battery you bought. There are now dozens and dozens of imported-from-China LiFePO4 batteries being sold via on-line websites.

Re: 190 Outrage Trolling Motor Installation

The batteries I bought were made by Chins.

[Moderator’s note: this thread is now closed. If others want to solicit advice on similar projects, please start a new thread, giving explicit details about you new project. A year has passed without comment from the thread originator regarding his plans to make a modification to his boat. If a modification was made, a new thread should be started to inform readers of the outcome.]

[Moderator’s note: this thread is now closed. If others want to solicit advice on similar projects, please start a new thread, giving explicit details about you new project. A year has passed without comment from the thread originator regarding his plans to make a modification to his boat. If a modification was made, a new thread should be started to inform readers of the outcome.]