Any boat left in salt or fresh water for more than a few days should have the gelcoat surface protected with a two-part epoxy paint followed by an anti-fouling paint. This will retard marine growth and help protect gelcoat from possible blistering. DO NOT LEAVE YOUR BOAT IN THE WATER FOR ANY EXTENDED TIME WITHOUT BOTTOM PAINT.

In choosing the type of anti-fouling paint, consult with your friends or dealers and purchase the type most effective or most popular in your area. Mask the hull and apply the anti-fouling paint according to the specific instructions of the paint manufacturer. Most will recommend priming or etching the gelcoat with a wash. Do not short cut this or the anti-fouling paint will not adhere properly.

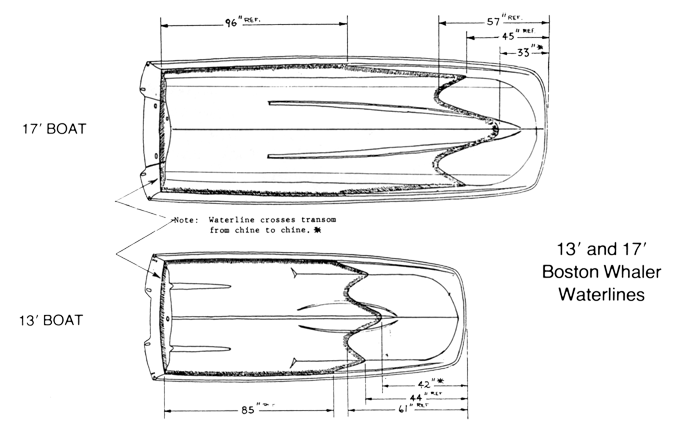

Approximate water line drawings for all models 18 thru 25 are available. However, these may vary slightly because of the variety of engine combinations and individual equipment on each boat. The best method to determine the exact water line on our boat is to launch and mark the bow and stern. The boat can then be hauled, leveled athwart ship, and trimmed fore and aft so the bow and stem marks are equal distance from the level floor. A piece of wood cut to the distance between the floor and the marks can be used to guide further marks completely around the hull. Mask off to this line. Raising the water line to be two or three inches higher than the float line will prevent scum marks from appearing on the gelcoat.

Gelcoat is the outer cosmetic skin on the boat. It is a durable layer of pigmented resin which makes routine maintenance relatively simple. The best way to keep the gelcoat on your boat looking fresh is by regular routine maintenance. Cleaning gelcoat should be done with a mild household detergent or boat soap followed by a rinse down with plenty of fresh water. A good coat of wax—either automotive or boat wax—at least twice a year will help maintain the smooth, glossy finish and protect the boat's surface. Do not wax surfaces that may be walked on, as they will become quite slippery when wet. Most of these areas have a non-skid surface molded in. Cleaning the non-skid surface is best accomplished with a scrub brush.

Gelcoat is a very durable material, but it can chip, crack, scratch or blister over the years and use. These are all cosmetic conditions which can usually be repaired easily and do not affect structure. Matching gelcoat and hull repair kits are available from your local dealer or Boston Whaler. These kits contain a detailed instruction sheet for most minor repairs. [Also see an illustrated repair article in the Reference Section.]

The following steps will assist you in maintaining your boat's canvas.

Teak is used on your Boston Whaler because of its beauty and easy maintenance. Teak weathers well because of natural oils in the wood, however, after repeated exposure it will turn gray. Teak should be cleaned with detergent or commercially available teak cleaner and re-oiled to return it to its natural color.

The varnish used on our woodwork is urethane, sprayed directly onto the wood without fillers or stains. By thinning the first of three coats, the urethane penetrates deeply into the pores, providing good holding power for subsequent coats. This is a very durable coating, and it forms a good base for any other type varnish.

The best maintenance for mahogany is to reduce exposure of the wood to weather and ultraviolet sun rays. This can be accomplished by equipping the boat with any of several varieties of console, seat, and mooring covers available.

Automotive wax or spray wax, such as Lemon Pledge, will add gloss and lustre to woodwork and add longevity to its surface. However, when refinishing time comes, great care will have to be taken to remove all the wax before sanding. If this precaution is not taken, you will sand the wax into the woodwork, and failure of new varnish will result. Remember, varnished surfaces will be slippery.

In refinishing, any good urethane varnish is acceptable and we suggest the use of one with which you or your acquaintances have had experience. There are two important warnings: (1) If you don't remove the woodwork from the boat, carefully mask all the deck surfaces with heavy paper prior to varnishing. A varnish drip will make a permanent black stain on the gelcoat which is impossible to remove. (2) Carefully sand all the surface areas prior to applying new coatings to kill ninety percent of the gloss. This gives "teeth" to retain the new material. Use fine sandpaper (#360). Use of course paper will cause scratches which will show after varnishing and will make it necessary to apply multiple coats to obtain original lustre. Sandpaper of the "open coat" type works well because the powered varnish does not clog the grit. Most varnish removers will not penetrate the urethane finish, sanding is the best method. The use of a vibrator sander will help. Do not use a circular sander as it will leave swirl marks in the finish.

The deck hardware on your Boston Whaler is made of various metals, all suited for a particular strength requirement. All rails, fastenings, and much of the hardware is stainless steel.

Stainless steel, although strong and corrosion resistant, does require regular periodic maintenance. Stainless steel surfaces must be kept clean and free of accumulated dirt and grit. Crevice corrosion, a brownish coloring, can occur on stainless components where one piece of stainless hardware joins another.

This condition is usually caused by impurities in water and air and can be cleaned off easily with any marine metal polish using a sponge, cloth or small bristled brush (useful for getting into nooks and crannies). CAUTION—Never use steel or bronze wool for any cleaning applications! Tiny particles will fall off, getting into gelcoat and causing rust stains.

After cleaning, some owners wax hardware to make future maintenance easier. Stainless, like gelcoat, becomes slippery when waxed, so caution should be exercised.

If your boat is out of use during the winter months or is laid-up for an extended time, the following should be done:

DISCLAIMER: This information is believed to be accurate but there is no guarantee. We do our best!

Portions Copyright © 2005 by James W. Hebert. Unauthorized reproduction prohibited!

This is a verified HTML 4.0 document served to you from continuousWave

URI: http://continuouswave.com

Author: Adapted to HTML by James W. Hebert

This article first appeared February 5, 2005.