Raising Engine Height

Raising Engine Height

On my older 16-footer with non-smirk hull, I have a Yamaha 90-HP two-stroke-power-cycle engine mounted using the blind mounting bosses for the lower mounting bolts--a very neat and well-done installation.

If I fill these existing lower engine mounting holes, and drill new lower engine mounting holes so the engine mounting height will have to be at least two-holes-up, I have some concern about having the engine mounted too high. My recollection is that most who have done this have had good luck [that is, have had satisfactory outcome with the two-holes-up engine mounting height]

[To readers who have changed the engine mounting height on an older 16-footer to be two-holes-up from a lower position that was using the blind boss holes], tell me if all the work [in repairing the old holes, drilling new holes, and remounting the engine at a two-holes-up position] was worth [the time and labor and expense].

If I fill these existing lower engine mounting holes, and drill new lower engine mounting holes so the engine mounting height will have to be at least two-holes-up, I have some concern about having the engine mounted too high. My recollection is that most who have done this have had good luck [that is, have had satisfactory outcome with the two-holes-up engine mounting height]

[To readers who have changed the engine mounting height on an older 16-footer to be two-holes-up from a lower position that was using the blind boss holes], tell me if all the work [in repairing the old holes, drilling new holes, and remounting the engine at a two-holes-up position] was worth [the time and labor and expense].

Re: Raising Engine Height

I presume that the present engine mounting height must be at the lowest possible position using the BIA layout for the top holes and blind holes. Please confirm if that is the actual present engine mounting height.

Re: Raising Engine Height

Yes, I am at the lowest mounting holes which puts the keel bottom and cavitation plate dead level.

Re: Raising Engine Height

Walt --you should fill the lower holes and drill new bottom holes following the BIA template.

Fill the existing lower holes with wood plugs dipped in epoxy. Shave off last plug flush. Cover with Locktite Marine Epoxy in white. It is a close color match to desert tan.

Confirm the existing top holes are 1-7/8" down from the top of the transom.

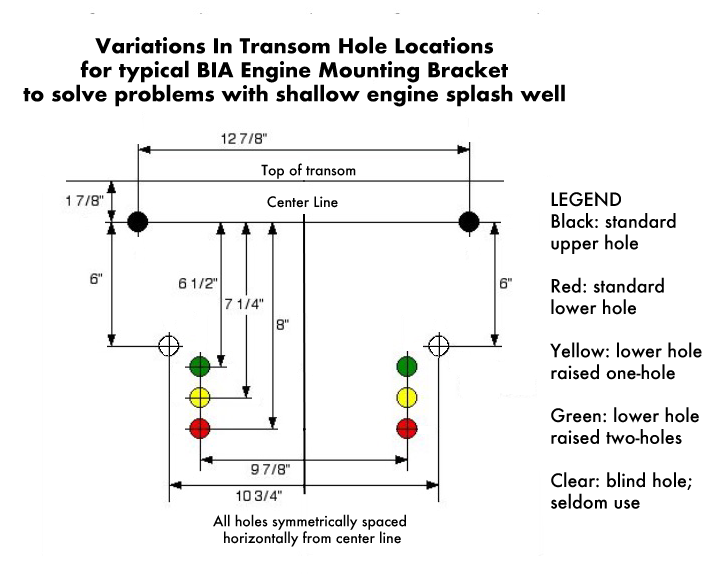

See the pinned article at the top of this forum for a diagram showing the BIA transom hole layout:

https://continuouswave.com/forum/viewto ... f=7&t=5808

Fig. 1. Image from linked article above on engine mounting height.

[The entire purpose of the linked article is to stop the need to post the same image over and over and to explain much more clearly what the image is trying to illustrate.--Moderator]

When you mount the engine, the top bolt should go into the third hole down from the top on the engine bracket. This will allow the new bottom holes to be in the upper half of the slot.

Fill the existing lower holes with wood plugs dipped in epoxy. Shave off last plug flush. Cover with Locktite Marine Epoxy in white. It is a close color match to desert tan.

Confirm the existing top holes are 1-7/8" down from the top of the transom.

See the pinned article at the top of this forum for a diagram showing the BIA transom hole layout:

https://continuouswave.com/forum/viewto ... f=7&t=5808

Fig. 1. Image from linked article above on engine mounting height.

[The entire purpose of the linked article is to stop the need to post the same image over and over and to explain much more clearly what the image is trying to illustrate.--Moderator]

When you mount the engine, the top bolt should go into the third hole down from the top on the engine bracket. This will allow the new bottom holes to be in the upper half of the slot.

1992 Outrage 17

2019 E-TEC 90

2018 LoadRite 18280096VT

Member since 2003

2019 E-TEC 90

2018 LoadRite 18280096VT

Member since 2003

Re: Raising Engine Height

Okay, let me confirm the height of the upper holes to be sure they are at 1-7/8-inch [on center below the top of the transom]

Re: Raising Engine Height

The top bolts are at 1 7/8-inch, and 2-1/8-inch other side.

The lowest I can drill from there is only 6-1/-inches before getting into the flare of the [engine splash] well bottom.

I am buying an inexpensive manual jack plate: , a KUAFU 4'' Set Back Jack Plate, $165. Sure it's made in China--or worst--but what isn't today. The made-in-China jack plate looks just like the Vance that sells for $450.

The lowest I can drill from there is only 6-1/-inches before getting into the flare of the [engine splash] well bottom.

I am buying an inexpensive manual jack plate: , a KUAFU 4'' Set Back Jack Plate, $165. Sure it's made in China--or worst--but what isn't today. The made-in-China jack plate looks just like the Vance that sells for $450.

Re: Raising Engine Height

I don't understand what you mean by the notation "other side."Blackduck wrote:The top bolts are at 1-7/8-inch, and 2-1/8-inch other side.

Are you measuring the distance of the center of the upper mounting holes below the top edge of the transom?

About all I can guess you mean by "other side" is that the distance from the top of the transom varies between the inboard face of the transom and the outboard face of the transom, which perhaps is what you were trying to describe with "other side."

If my guess is correct, identify which side of the transom has which hole spacing for the top set of holes.

For the distance of the holes below the top of the transom to be 1/4-inch different suggests this set of holes may have been drilled on an angle through the transom. Or perhaps someone has modified the top edge of the transom to no longer be square to the vertical plane of the transom. The holes should be drilled so they are at 90-degrees to the outboard plane of the transom.

How much does the Made-in-China engine jack plate weigh?

Re: Raising Engine Height

The jack plate weighs 19 pounds.

The person drilling the top holes drilled them 1/4" different. If he didn't use a jig, easy to do. Motor does seat tight to top of transom on both side, so may have been intentional.

The person drilling the top holes drilled them 1/4" different. If he didn't use a jig, easy to do. Motor does seat tight to top of transom on both side, so may have been intentional.

Re: Raising Engine Height

I think you are trying to confirm that your measurements referring to "the other side" were in reference to the transom holes exiting the transom at different heights below the top of the transom on the inboard side and the outboard side.Blackduck wrote:The person drilling the top holes drilled them 1/4-inchdifferent.

Re: Raising Engine Height

I would not do the bracket.

I think my color blindedness has caused a mistake.

The hole I am suggesting is above the yellow hole.

If you measure the engine bracket, how far is the distance from the center of the top slot to the 3rd hole from the top? Add 2" to that. What is the number?

See my email?

I think my color blindedness has caused a mistake.

The hole I am suggesting is above the yellow hole.

If you measure the engine bracket, how far is the distance from the center of the top slot to the 3rd hole from the top? Add 2" to that. What is the number?

See my email?

1992 Outrage 17

2019 E-TEC 90

2018 LoadRite 18280096VT

Member since 2003

2019 E-TEC 90

2018 LoadRite 18280096VT

Member since 2003

Re: Raising Engine Height

Blackduck wrote:The jack plate weighs 19 pounds.

The person drilling the top holes drilled them 1/4" different. If he didn't use a jig, easy to do. Motor does seat tight to top of transom on both side, so may have been intentional.

For an additional 5-lbs you could have a hydraulic jack plate with lots of adjustability. I run one of my 15-footer and love it.

Fig. 2. 15-footer transom with hydraulically operated jack plate.

D-

Re: Raising Engine Height

Phil--I didn't see email because it's broken, but I should have it straightened out by June 16, 2022.

6-1/2-inches between third hole and top of slot.

Add 2-inches

8-1/2-inches.

Why add 2-inches

Dave--good looking installation.

6-1/2-inches between third hole and top of slot.

Add 2-inches

8-1/2-inches.

Why add 2-inches

Dave--good looking installation.

Last edited by Blackduck on Fri Jun 17, 2022 10:30 am, edited 1 time in total.

Re: Raising Engine Height

Blackduck wrote:6-1/2-inches between third hole and top of slot.

Add 2-inches

8-1/2-inches.

Why add 2-inches

Describing in a narrative a complicated layout of holes with explicit dimensions is not a very good method.

Perhaps a sketch of what the narrative was trying to describe might be more useful.

In any case, if the transom holes are drilled according the BIA hole layout discussed already, and if the lower engine mounting hole is set is spaced 6-1/2-inches below the upper hole set, then the engine will need to be installed AT A MINIMUM HEIGHT of two-holes-up from lowest position.

If the engine mounting plate has a slot for the lower bolts to fit through, and the range of adjustment in the slot will accommodate raising the engine to as high as three-holes-up from lowest, then if the bottom bolts are fitted to holes that are 6-1/2-inches below the upper holes, those bolts should be at the top of the slot. That is because the mounting height is two-holes up (0.75 x 2 = 1.5) AND the bolt holes are two-holes-up. The result is that the bolts will end up right at the top of the slots. That is WHY we keep informing you that IF you drill the lower mounting holes 1.5-inches higher than normal, you will have to mount the engine AT LEAST two-holes up.

I will now stand by for another round of discussion on these dimensions.

And, by the way, I have no idea where the "2-inches" comes into play in any of this.

ASIDE: I agree with Phil--don't get the jack plate. I would just leave the engine right where it is now, mounted in the lowest possible position. You are going to undertake a lot of work and rework to do anything else. What will you gain: maybe a few hundred RPM in maximum engine speed at full-throttle. But if you are hungry for a big project, go ahead with the changes suggested.

Re: Raising Engine Height

My intent in placing this post was to get some feedback from those who have [performed all the work needed to replace a blind-hole mounting with a lower transom mounting hole in an elevated location from the normal BIA location to overcome the problem os a shallow engine splash well on an older Boston Whaler boat].

I agree that the net gain in performance is most likely minimal. But I am hung up on doing things right and enjoying the process. Hearing one person vote against it is good for me.

I'm not sure if Phil is against or for the change in general, just against the plate.

I agree that the net gain in performance is most likely minimal. But I am hung up on doing things right and enjoying the process. Hearing one person vote against it is good for me.

I'm not sure if Phil is against or for the change in general, just against the plate.

Re: Raising Engine Height

With the risk of insulting Phil and Jimh, you really need to find someone that has done something similar on that model hull. Taking advice from those with an adversion to jackplates or anything non-Whaler without having personal experience to the use of a jackplate on that hull (or very similar) isn't doing yourself any favors.

I know there were people grumbling about adding a jackplate to my 15' and now that I have it, I would never go back to running the boat without.

I'm able to run my motor nearly 7" above the transom. And as I raise the motor, the boat feels better with steering input and you can hear the motor pickup speed. When I idle down and in shallow water it makes a difference as well with engine draft.

Is a jackplate for everyone - NO, but there's a number of people that use them and are very pleased with the results.

D-

I know there were people grumbling about adding a jackplate to my 15' and now that I have it, I would never go back to running the boat without.

I'm able to run my motor nearly 7" above the transom. And as I raise the motor, the boat feels better with steering input and you can hear the motor pickup speed. When I idle down and in shallow water it makes a difference as well with engine draft.

Is a jackplate for everyone - NO, but there's a number of people that use them and are very pleased with the results.

D-

Re: Raising Engine Height

With respect to Dave, who knows far more than me, I look at boats and boating with a minimalist approach.

In my head it's easier and cheaper to plug the existing lower holes and raise the engine 2 holes so it operates well at all speeds.

Almost all my boating has been in the snotty, cold, foggy and downright nasty Gulf of Maine. I lived on an island for a time so reliability and simplicity are my core values.

If you want speed and boat in waters that allow high speed, then absolutely, go with a hydraulic jack-plate and tune that to an inch of its life.

It's not be about me.

What do you want to do?

In my head it's easier and cheaper to plug the existing lower holes and raise the engine 2 holes so it operates well at all speeds.

Almost all my boating has been in the snotty, cold, foggy and downright nasty Gulf of Maine. I lived on an island for a time so reliability and simplicity are my core values.

If you want speed and boat in waters that allow high speed, then absolutely, go with a hydraulic jack-plate and tune that to an inch of its life.

It's not be about me.

What do you want to do?

1992 Outrage 17

2019 E-TEC 90

2018 LoadRite 18280096VT

Member since 2003

2019 E-TEC 90

2018 LoadRite 18280096VT

Member since 2003

-

Tom Hemphill

- Posts: 81

- Joined: Fri Oct 16, 2015 5:04 pm

Re: Raising Engine Height

I hope I can provide the first-person advice being sought:

When I bought my 1970 16-foot Whaler, its 90-HP Evinrude ETEC outboard was mounted at the lowest possible position, using the blind lower holes. When I decided to upgrade to a stainless steel propeller, I took the opportunity to also re-drill my lower transom holes to meet modern standards.

I filled and re-drilled the bottom holes 6-1/2 inches below the upper holes (the "green holes"). I didn't dare go any lower; this means I have just the two highest motor mounting heights to choose from. I mounted my outboard "all the way up" and it's completely fine in choppy seas, swells and tight turns.

I took on this project to achieve modest performance inreases, and to prepare the boat for a new outboard when that time eventually comes. It was successful doing that, and I didn't find the work to be particularly difficult or expensive.

I feel there is no good reason to add a jackplate, and there are many arguments against it.

When I bought my 1970 16-foot Whaler, its 90-HP Evinrude ETEC outboard was mounted at the lowest possible position, using the blind lower holes. When I decided to upgrade to a stainless steel propeller, I took the opportunity to also re-drill my lower transom holes to meet modern standards.

I filled and re-drilled the bottom holes 6-1/2 inches below the upper holes (the "green holes"). I didn't dare go any lower; this means I have just the two highest motor mounting heights to choose from. I mounted my outboard "all the way up" and it's completely fine in choppy seas, swells and tight turns.

I took on this project to achieve modest performance inreases, and to prepare the boat for a new outboard when that time eventually comes. It was successful doing that, and I didn't find the work to be particularly difficult or expensive.

I feel there is no good reason to add a jackplate, and there are many arguments against it.

Re: Raising Engine Height

TOM--thank you for jumping in with your first-hand experiences.

Re: Raising Engine Height

Yes, thanks all for the input on this situation. I think getting away from the blind hole mounting system seems to be a good thing for me to strongly consider. My thoughts are that using some sort of setback mounting plate will solve the problem with the least amount of work. Filling and drilling new holes is time consuming and a bit hairy. If paying for the job, it would cost more to fill and re drill than just buying a set back plate. I am know leaning towards a Bob's Machine fixed set back plate. Made in USA, made of a known material, and very rugged construction, 5/8" aluminum. The 4" of set back seems to have advantages, and I will allow me to adjust height of the engine by the full amount of the engine's own mounting system. Going to think about it a bit more-

Re: Raising Engine Height

Tom Hemphill wrote:I hope I can provide the first-person advice being sought:

When I bought my 1970 16-foot Whaler, its 90-HP Evinrude ETEC outboard was mounted at the lowest possible position, using the blind lower holes. When I decided to upgrade to a stainless steel propeller, I took the opportunity to also re-drill my lower transom holes to meet modern standards.

I filled and re-drilled the bottom holes 6-1/2 inches below the upper holes (the "green holes"). I didn't dare go any lower; this means I have just the two highest motor mounting heights to choose from. I mounted my outboard "all the way up" and it's completely fine in choppy seas, swells and tight turns.

I took on this project to achieve modest performance inreases, and to prepare the boat for a new outboard when that time eventually comes. It was successful doing that, and I didn't find the work to be particularly difficult or expensive.

I feel there is no good reason to add a jackplate, and there are many arguments against it.

Great input Tom, from somone with the same model boat. The one thing I always steer clear of is advice where the person giving the advice has no personal experience with the advice given. The older 17' probably isn't best boat searching for speed or performance, but other hulls respond in a positive manner. The 15' Whaler behaves more like a bass boat hull and responds quite well to a jackplate.

Rest assured, it's not for all boats and I do not run one on my 21' center console since I can get the motor high enough after a full transom rebuild.

Phil and I do share a passion for the Maine Coast and have both lived in that same area, but my ocean time in Maine was further north by 100+ miles in the Matinicus Island, Bar Harbor up toward Canada. It's a paradise up in that area.

D-

Re: Raising Engine Height

Putting the jack plate concern aside, I am now unsure as to how Tom and Dave feel about raising the engine 1-1/2-inches on a pre-smirk hull. Is it worth it, or not?

Re: Raising Engine Height

My approach to life has never been to say "good enough". I have always tried to do a little better than the guy before me, and at 73, I'd have to say that it has worked out pretty darn well for me. I am probably going to make the motor mounts adjustable, so that I can adjust the engines operating height to my hearts content. My only hope is that I will be able to get into the darn boat when I get it back in the water sometime in May 2022.

Re: Raising Engine Height

Good luck with your project.

Before making any changes, you should document the boat performance with the engine mounted as it has always been.

When you complete the project, perhaps you can provide some data about boat performance-- before and after the change in engine mounting height and set back distance--so that others can learn what effect the project actually had on the boat.

I am sure you will gather all that data and give readers a chance to see the difference that occurred from all that work.

Also, you should mention all the details about the boat that are missing in this discussion. Any really useful data about performance needs comprehensive information about the boat, the engine, the propeller, the measuring gear, and so on.

ASIDE: regarding trying to do things "a little better than the guy before me," that is admirable, but in this case the guy before you the head of Boston Whaler boat design; it is always a challenge to improve on the best.

Before making any changes, you should document the boat performance with the engine mounted as it has always been.

When you complete the project, perhaps you can provide some data about boat performance-- before and after the change in engine mounting height and set back distance--so that others can learn what effect the project actually had on the boat.

I am sure you will gather all that data and give readers a chance to see the difference that occurred from all that work.

Also, you should mention all the details about the boat that are missing in this discussion. Any really useful data about performance needs comprehensive information about the boat, the engine, the propeller, the measuring gear, and so on.

ASIDE: regarding trying to do things "a little better than the guy before me," that is admirable, but in this case the guy before you the head of Boston Whaler boat design; it is always a challenge to improve on the best.